August 2017

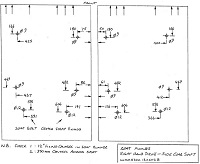

To fit the seats and seat belts we need to drill some holes in the floor pan. The build manual comes with a number of diagrams showing the location of the holes for various gearshift configurations. I have the G50 with right hand rod shifter.

The holes are referenced to edges of the floor pan, but with the lowered floor this becomes a bit of a challenge as the reference points to measure from are on the edges of the un-lowered section. To add to the challenge the seats are located at a slight angle so the holes do not run parallel with the reference edges of the floor pan. The holes in the runners are 12" apart and the runners are located 350mm apart.

If the holes are not reasonably accurately located then apart from the obvious difficulty of inserting all of the seat runner bolts,there may be binding when moving the seats on the runners.

To assist in locating I use an engineers square along with a steel rule.

As a final check I also measure between the holes and verify the 12" and 350mm dimensions, I also measure diagonally between the holes on the seat runners when fitted to the seats and compare with my markings on the floor pan.

With the seats installed I find that when I seated I have trouble reaching the pedals even with the seat fully moved forward.

Closer examination reveals that the seat movement forward is restricted by the front edge of the lowered floor pan.

To overcome this I need to raise the seat to allow the runners to clear the lowered floor pan lip.

I decide to fabricate some box section steel to elevate the seats by the required amount.

I felt that if I just drilled clearance holes and installed longer bolts to secure the seats then there was a chance of the box section collapsing over time allowing the bolts to become loose or overtighting of the bolts could equally begin to collapse the section. To satisfy myself I machine some steel inserts to slide into the box section.

The blocks are drilled and tapped and then when located in the steel box section are tacked in with a couple of beads of weld. Once completed the risers are given a quick coat of black paint and fitted to the driver seat with some button head screws that screw down through the rails and into the blocks, care was taken to ensure that the length of the screws was such that they did not extend more than half way into the blocks - we need threads on the other side to screw the completed runners to the floor pan from underneath.

There is no need to raise the passenger seat so to make the fitting easier some nuts were tacked to the runners and repainted.

Both seats were then fitted using some more button head screws through the floor pan from underneath, although they will have to be removed to fit the carpet.